Large quantity of steel sheet piles customized by preferential manufacturers

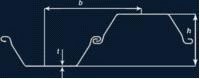

Profile Structure

Steel sheet pile cofferdam is the most commonly used one. The steel sheet pile is a kind of section steel with a locking mouth. Its section includes straight plate, slot and Z shape, and has various sizes and interlocking forms. The common ones are Larsen style, Lavanna style, etc.

Its advantages are: high strength, easy to drive into hard soil layer; Construction can be carried out in deep water, and inclined support can be added to form a cage if necessary. Good waterproof performance; It can form cofferdams of various shapes as required and can be reused for many times. Therefore, it is widely used.

Cofferdam at the top of open caisson is often used in bridge construction, and it is widely used. Cofferdam of pipe column foundation, pile foundation and open cut foundation, etc.

These cofferdams are mostly single-wall closed type. There are vertical and horizontal supports in the cofferdams. If necessary, oblique supports are added to form a cofferdam. For example, the pipe column foundation of the Yangtze River Bridge in Nanjing, China, used to use a steel sheet pile circular cofferdam with a diameter of 21.9 meters and a steel sheet pile length of 36 meters. There are various sizes and interlocking forms. After the underwater concrete bottom reaches the strength requirements, the pile cap and pier body shall be constructed by pumping water, and the design depth of pumping water shall reach 20 meters.

In hydraulic construction, the construction area is generally large, and it is often used to make structural cofferdam. It is composed of many interconnected single bodies, each of which is composed of many steel sheet piles, and the middle of the single body is filled with soil. The scope of the cofferdam is very large, and the cofferdam wall cannot be supported by support. Therefore, each single body can independently resist overturning, sliding and prevent the tension crack at the interlock. Commonly used are round and partition shapes.

1. Steel sheet pile

2. Joint structure on both sides

3. Form walls in the ground and water

Material Parameters

Cold-formed steel plate

The steel sheet pile continuously cold-forms the steel strip to form a plate for building foundation with a section of Z shape, U shape or other shapes that can be connected with each other through the lock.

The steel sheet pile produced by the method of rolling cold bending is one of the main products of cold bending steel used in civil engineering. The steel sheet pile is driven (pressed) into the foundation with a pile driver to connect them to form a steel sheet pile wall for retaining soil and water. Common section types include U-shaped, Z-shaped and straight-web plate. Steel sheet pile is suitable for soft foundation and deep foundation pit support with high groundwater level. It is easy to construct. Its advantages are good water stop performance and can be reused. Delivery status of steel sheet pile The delivery length of cold-formed steel sheet pile is 6m, 9m, 12m, 15m, and it can also be processed according to the user's requirements. The maximum length is 24m. (If the user has special length requirements, they can be put forward when ordering) The cold-formed steel sheet piles can be delivered according to the actual weight or the theoretical weight. Application of steel sheet pile The cold-formed steel sheet pile product has the characteristics of convenient construction, fast progress, no need of huge construction equipment, and is conducive to seismic design in civil engineering applications. It can also change the section shape and length of cold-formed steel sheet pile according to the specific situation of the project, so as to make the structural design more economic and reasonable. In addition, through the optimization design of the section of the cold-formed steel sheet pile product, the quality coefficient of the product has been significantly improved, the weight per meter of pile wall width has been reduced, and the engineering cost has been reduced. [1]

Technical parameter

According to production process, steel sheet pile products are divided into two types: cold-formed thin-walled steel sheet pile and hot-rolled steel sheet pile. In engineering construction, the application range of cold-formed steel sheet piles is relatively narrow, and most of them are used as a supplement to the applied materials. Hot-rolled steel sheet piles have always been the leading products in engineering applications. Based on the many advantages of steel sheet piles in construction, the State Administration of Quality Supervision, Inspection and Quarantine and the National Standardization Administration issued the national standard "Hot rolled U-shaped steel sheet piles" on May 14, 2007, which was officially implemented on December 1, 2007. At the end of the 20th century, Masteel Co., Ltd. produced more than 5000 tons of U-shaped steel sheet piles with a width of 400 mm by virtue of the technological equipment conditions of the universal rolling mill production line imported from abroad, and successfully applied them to the cofferdam of Nenjiang Bridge, the 300000 ton dock of Jingjiang New Century Shipyard and the flood control project in Bangladesh. However, due to the low production efficiency, poor economic benefits, low domestic demand and insufficient technical experience during the trial production period, the production could not be sustained. According to statistics, at present, the annual consumption of steel sheet piles in China remains around 30000 tons, accounting for only 1% of the global total, and is limited to some permanent projects such as port, wharf and shipyard construction and temporary projects such as bridge cofferdam and foundation pit support.

The cold-formed steel sheet pile is a steel structure that is formed by continuous rolling of the cold-formed unit, and the side lock can be continuously overlapped to form a sheet pile wall. The cold-formed steel sheet pile is made of thinner plates (usually 8 mm~14 mm thick) and processed by cold-formed forming unit. Its production cost is low and the price is cheap, and the sizing control is more flexible. However, due to the simple processing method, the thickness of each part of the pile body is the same, and the section size cannot be optimized, resulting in an increase in steel consumption; The shape of the locking part is difficult to control, and the connection is not tightly buckled and cannot stop water; Limited by the capacity of cold bending processing equipment, only products with low strength grade and thin thickness can be produced; In addition, the stress produced in the process of cold bending is relatively large, and the pile body is easy to tear in use, which has great limitations in application. In engineering construction, the application range of cold-formed steel sheet piles is relatively narrow, and most of them are only used as a supplement to the applied materials. Features of cold-formed steel sheet pile: according to the actual situation of the project, the most economical and reasonable section can be selected to achieve the optimization of the project design, saving 10-15% of the material compared with the hot-rolled steel sheet pile with the same performance, greatly reducing the construction cost.

Type introduction

Basic introduction of U-shaped steel sheet pile

1. The section structure design of WR series steel sheet piles is reasonable, and the forming technology is advanced, which makes the ratio of section modulus and weight of steel sheet pile products continuously increase, so that it can obtain good economic benefits in application and broaden the application field of cold-formed steel sheet piles.

2. WRU steel sheet pile has a variety of specifications and models.

3. Designed and produced according to the European standard, the symmetrical structure is conducive to repeated use, which is equivalent to hot rolling in terms of repeated use, and has a certain angle amplitude, which is convenient for correcting construction deviation.

4. The use of high-strength steel and the advanced production equipment ensure the performance of cold-formed steel sheet piles.

5. The length can be customized according to the customer's requirements, which brings convenience to the construction and reduces the cost.

6. Due to the convenience of production, it can be pre-ordered before delivery when used with composite piles.

7. The production design and production cycle are short, and the performance of steel sheet piles can be determined according to customer requirements.

Legend and advantages of U-shaped series cold-formed steel sheet pile

1. U-shaped steel sheet piles have various specifications and models.

2. It is designed and produced according to European standards, with symmetrical structural form, which is conducive to reuse, and is equivalent to hot rolling in terms of reuse.

3. The length can be customized according to the customer's requirements, which brings convenience to the construction and reduces the cost.

4. Due to the convenience of production, it can be pre-ordered before delivery when used with composite piles.

5. The production design and production cycle are short, and the performance of steel sheet piles can be determined according to customer requirements.

Common specifications of u-shaped steel sheet pile

| Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| WRU7 | 750 | 320 | 5 | 71.3 | 42.0 | 56.0 | 10725 | 670 |

| WRU8 | 750 | 320 | 6 | 86.7 | 51.0 | 68.1 | 13169 | 823 |

| WRU9 | 750 | 320 | 7 | 101.4 | 59.7 | 79.6 | 15251 | 953 |

| WRU10-450 | 450 | 360 | 8 | 148.6 | 52.5 | 116.7 | 18268 | 1015 |

| WRU11-450 | 450 | 360 | 9 | 165.9 | 58.6 | 130.2 | 20375 | 1132 |

| WRU12-450 | 450 | 360 | 10 | 182.9 | 64.7 | 143.8 | 22444 | 1247 |

| WRU11-575 | 575 | 360 | 8 | 133.8 | 60.4 | 105.1 | 19685 | 1094 |

| WRU12-575 | 575 | 360 | 9 | 149.5 | 67.5 | 117.4 | 21973 | 1221 |

| WRU13-575 | 575 | 360 | 10 | 165.0 | 74.5 | 129.5 | 24224 | 1346 |

| WRU11-600 | 600 | 360 | 8 | 131.4 | 61.9 | 103.2 | 19897 | 1105 |

| WRU12-600 | 600 | 360 | 9 | 147.3 | 69.5 | 115.8 | 22213 | 1234 |

| WRU13-600 | 600 | 360 | 10 | 162.4 | 76.5 | 127.5 | 24491 | 1361 |

| WRU18-600 | 600 | 350 | 12 | 220.3 | 103.8 | 172.9 | 32797 | 1874 |

| WRU20-600 | 600 | 350 | 13 | 238.5 | 112.3 | 187.2 | 35224 | 2013 |

| WRU16 | 650 | 480 | 8. | 138.5 | 71.3 | 109.6 | 39864 | 1661 |

| WRU 18 | 650 | 480 | 9 | 156.1 | 79.5 | 122.3 | 44521 | 1855 |

| WRU20 | 650 | 540 | 8 | 153.7 | 78.1 | 120.2 | 56002 | 2074 |

| WRU23 | 650 | 540 | 9 | 169.4 | 87.3 | 133.0 | 61084 | 2318 |

| WRU26 | 650 | 540 | 10 | 187.4 | 96.2 | 146.9 | 69093 | 2559 |

| WRU30-700 | 700 | 558 | 11 | 217.1 | 119.3 | 170.5 | 83139 | 2980 |

| WRU32-700 | 700 | 560 | 12 | 236.2 | 129.8 | 185.4 | 90880 | 3246 |

| WRU35-700 | 700 | 562 | 13 | 255.1 | 140.2 | 200.3 | 98652 | 3511 |

| WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

| WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

| WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

| WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

| WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

| WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

| WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

| WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

| WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

| WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

| WRU 38 | 750 | 602 | 13 | 253.7 | 149.4 | 199.2 | 115505 | 3837 |

| WRU 40 | 750 | 598 | 14 | 282.2 | 166.1 | 221.5 | 119918 | 4011 |

| WRU 43 | 750 | 600 | 15 | 301.5 | 177.5 | 236.7 | 128724 | 4291 |

| WRU 45 | 750 | 602 | 16 | 320.8 | 188.9 | 251.8 | 137561 | 4570 |

Z-shaped steel sheet pile

The locking openings are symmetrically distributed on both sides of the neutral axis, and the web is continuous, which greatly improves the section modulus and bending stiffness, and ensures that the mechanical properties of the section can be fully developed. Because of its unique section shape and reliable Larssen lock.

Advantages and icons of Z-shaped steel sheet pile

1. Flexible design with relatively high section modulus and mass ratio.

2. Higher inertia moment increases the rigidity of the sheet pile wall and reduces the displacement and deformation.

3. Large width, effectively saving the time of hoisting and piling.

4. With the increase of section width, the number of shrinkages of sheet pile wall is reduced, and its water sealing performance is directly improved.

5. The severely corroded parts have been thickened, and the corrosion resistance is more excellent.

Common specifications of Z-shaped steel sheet pile

| Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| WRZ16-635 | 635 | 379 | 7 | 123.4 | 61.5 | 96.9 | 30502 | 1610 |

| WRZ18-635 | 635 | 380 | 8 | 140.6 | 70.1 | 110.3 | 34717 | 1827 |

| WRZ28-635 | 635 | 419 | 11 | 209.0 | 104.2 | 164.1 | 28785 | 2805 |

| WRZ30-635 | 635 | 420 | 12 | 227.3 | 113.3 | 178.4 | 63889 | 3042 |

| WRZ32-635 | 635 | 421 | 13 | 245.4 | 122.3 | 192.7 | 68954 | 3276 |

| WRZ12-650 | 650 | 319 | 7 | 113.2 | 57.8 | 88.9 | 19603 | 1229 |

| WRZ14-650 | 650 | 320 | 8 | 128.9 | 65.8 | 101.2 | 22312 | 1395 |

| WRZ34-675 | 675 | 490 | 12 | 224.4 | 118.9 | 176.1 | 84657 | 3455 |

| WRZ37-675 | 675 | 491 | 13 | 242.3 | 128.4 | 190.2 | 91327 | 3720 |

| WRZ38-675 | 675 | 491.5 | 13.5 | 251.3 | 133.1 | 197.2 | 94699 | 3853 |

| WRZ18-685 | 685 | 401 | 9 | 144 | 77.4 | 113 | 37335 | 1862 |

| WRZ20-685 | 685 | 402 | 10 | 159.4 | 85.7 | 125.2 | 41304 | 2055 |

L/S steel sheet pile

L-type is mainly used for the support of embankment, dam wall, channel excavation and trenching.

The section is light, the space occupied by the pile wall is small, the lock is in the same direction, and the construction is convenient. It is applicable to excavation construction of municipal engineering.

| Common specifications of L-shaped steel sheet pile | |||||||

| Type | Width | Height | Thickness | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| WRL1.5 | 700 | 100 | 3.0 | 21.4 | 30.6 | 724 | 145 |

| WRL2 | 700 | 150 | 3.0 | 22.9 | 32.7 | 1674 | 223 |

| WRI3 | 700 | 150 | 4.5 | 35.0 | 50.0 | 2469 | 329 |

| WRL4 | 700 | 180 | 5.0 | 40.4 | 57.7 | 3979 | 442 |

| WRL5 | 700 | 180 | 6.5 | 52.7 | 75.3 | 5094 | 566 |

| WRL6 | 700 | 180 | 7.0 | 57.1 | 81.6 | 5458 | 606 |

|

Common specifications of s-shaped steel sheet pile |

|||||||

| Type | Width | Height | Thickness | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Kg/m | Kg/ m2 | Cm4/m | Cm3/m | |

| WRS4 | 600 | 260 | 3.5 | 31.2 | 41.7 | 5528 | 425 |

| WRS5 | 600 | 260 | 4.0 | 36.6 | 48.8 | 6703 | 516 |

| WRS6 | 700 | 260 | 5.0 | 45.3 | 57.7 | 7899 | 608 |

| WRS8 | 700 | 320 | 5.5 | 53.0 | 70.7 | 12987 | 812 |

| WRS9 | 700 | 320 | 6.5 | 62.6 | 83.4 | 15225 | 952 |

Another form of straight-type steel sheet pile is suitable for excavation of some ditches, especially when the space between two buildings is small and excavation is necessary, because its height is lower and close to the straight line.

Advantages and icons of linear steel sheet piles

First, it can form a stable steel sheet pile wall to ensure the smooth downward excavation without being affected by the treading on both sides and groundwater.

Second, it also helps to stabilize the foundation, thus ensuring the stability of buildings on both sides.

|

Common specifications of linear steel sheet pile |

|||||||||||||||||

| Type | Width mm | Height mm | Thickness mm | Sectional area cm2/ m | Weight | Moment of Inertia cm4/m | Modulus of section cm3/ m | ||||||||||

| Weight per pil kg/m | Weight per wallkg/m2 | ||||||||||||||||

| WRX 600-10 | 600 | 60 | 10.0 | 144.8 | 68.2 | 113.6 | 396 | 132 | |||||||||

| WRX600-11 | 600 | 61 | 11.0 | 158.5 | 74.7 | 124.4 | 435 | 143 | |||||||||

| WRX600-12 | 600 | 62 | 12.0 | 172.1 | 81.1 | 135.1 | 474 | 153 | |||||||||

| Standard for chemical composition and mechanical properties of cold-formed steel sheet pile materials GB/T700-1988 GB/T1591-1994 GB/T4171-2000 |

|||||||||||||||||

| Brand | Chemical composition | Mechanical property | |||||||||||||||

| C | Si | Mn | P | S | yield strengthMpa | tensile strengthMpa | Elongation | Impact energy | |||||||||

| Q345B | s0.20 | ≤0.50 | ≤1.5 | ≤0.025 | ≤0.020 | 2345 | 470-630 | ≥21 | 234 | ||||||||

| Q235B | 0.12-0.2 | s0.30 | 0.3-0.7 | ≤0.045 | ≤0.045 | ≥235 | 375-500 | 226 | 227 | ||||||||

Hot-rolled steel plate

Hot rolled steel sheet piles, as the name implies, are steel sheet piles produced by welding and hot rolling. Due to the advanced technology, its locking bite has tight water resistance.

Parameter example

| Section characteristics of hot-rolled steel sheet pile | ||||||||||||||||

| Type | Section size | Weight per pile | Weight per wall | |||||||||||||

| Width | Height | Thickness | Sectional area |

Theoretical weight | Moment of Inertia |

Modulus of section |

Sectional area | Theoretical weight |

Moment of Inertia |

Modulus of section |

||||||

| mm | mm | mm | cmz | cm2 | Kg/m | Cm3/m | cm7/m | cm2/m | Kg/m? | cm4 | cm3/m | |||||

| SKSP- Ⅱ | 400 | 100 | 10.5 | 61.18 | 48.0 | 1240 | 152 | 153.0 | 120 | 8740 | 874 | |||||

| SKSP-Ⅲ | 400 | 125 | 13.0 | 76.42 | 60.0 | 2220 | 223 | 191.0 | 150 | 16800 | 1340 | |||||

| SKSP-IV | 400 | 170 | 15.5 | 96.99 | 76.1 | 4670 | 362 | 242.5 | 190 | 38600 | 2270 | |||||

| Table of steel grade, chemical composition and mechanical property parameters of hot-rolled steel sheet pile | ||||||||||||||||

| Callout number | Type | Chemical composition | Mechanical analysis | |||||||||||||

| C | Si | Mn | P | S | N | Yield strength N/mm | Tensile strength N/mm | Elongation | ||||||||

| JIS A5523 | SYW295 | 0.18 max | 0.55 max | 1.5 max | 0.04 max | 0.04 max | 0.006 max | >295 | >490 | >17 | ||||||

| SYW390 | 0.18 max | 0.55 max | 1.5 max | 0.04 max | 0.04 3X | 0.006 max | 0.44 max | >540 | >15 | |||||||

| JIS A5528 | SY295 | 0.04 max | 0.04 max | >295 | >490 | >17 | ||||||||||

| SY390 | 0.04 max | 0.04 max | >540 | >15 | ||||||||||||

Shape Category

U-shaped steel sheet pile

Composite steel sheet piles

Characteristics

Application characteristics:

1. Handle and solve a series of problems in the mining process.

2. Simple construction and short construction period.

3. For the construction task, it can reduce the space requirements.

4. The use of steel sheet piles can provide necessary safety and have strong timeliness (for disaster relief).

5. The use of steel sheet piles can not be restricted by weather conditions; In the process of using steel sheet piles, it can simplify the complex procedures for checking the performance of materials or systems to ensure their adaptability, good interchangeability, and can be reused.

6. It can be recycled and reused to save money.

Hydraulic engineering - buildings along port transport routes - roads and railways

1. Wharf wall, maintenance wall and retaining wall;.

2. Construction of docks and shipyards and noise isolation walls.

3. Pier protection pile, (wharf) bollard, bridge foundation.

4. Radar rangefinder, slope, slope.

5. Sinking railway and groundwater retention.

6. Tunnel.

Civil works of waterway:

1. Maintenance of waterways.

2. Retaining wall.

3. Consolidate subgrade and embankment.

4. Berthing equipment; Prevent scouring.

Pollution control of water conservancy engineering buildings - polluted places, fence filling:

1. Ship locks, water locks, and vertical sealed fences (of rivers).

2. Weir, embankment, excavation for soil replacement.

3. Bridge foundation and water tank enclosure.

4. Culvert (highway, railway, etc.);, Protection of underground cable channel at the top slope.

5. Safety door.

6. Reduction of noise of flood control embankment.

7. Bridge column and wharf noise isolation wall;

8. Chemical composition and mechanical properties of cold-formed steel sheet pile materials. [1]

Advantages:

1. With strong bearing capacity and light structure, the continuous wall composed of steel sheet piles has high strength and rigidity.

2. The water tightness is good, and the lock at the connection of the steel sheet pile is tightly combined, which can naturally prevent seepage.

3. The construction is simple, can adapt to different geological conditions and soil quality, can reduce the excavation volume of foundation pit, and the operation occupies a small site.

4. Good durability. Depending on the difference in the use environment, the service life can be up to 50 years.

5. The construction is environmentally friendly, and the amount of soil and concrete taken is greatly reduced, which can effectively protect the land resources.

6. The operation is efficient, and is extremely suitable for rapid implementation of flood control, collapse, quicksand, earthquake and other disaster relief and prevention.

7. The materials can be recycled and reused for 20-30 times in temporary works.

8. Compared with other single structures, the wall is lighter and has greater adaptability to deformation, which is suitable for the prevention and treatment of various geological disasters.

Application

Function, appearance and practical value are the standards that people use when choosing building materials today. Steel sheet piles are in line with the above three points: the elements of its manufacturing components provide a simple and practical structure, meet all the requirements of structural safety and environmental protection, and the buildings completed by steel sheet piles have great attraction.

The application of steel sheet piles runs through and extends to the whole construction industry, from the use of traditional water conservancy engineering and civil technology, as well as the application of railway and tramway to the application of environmental pollution control.

The practical value of steel sheet piles has been reflected in the innovative production of many new products, such as: some special welded buildings; Metal plate made by hydraulic vibratory pile driver; Sealed sluice and factory paint treatment. Many factors ensure that steel sheet piles maintain one of the most useful manufacturing component elements, that is, it is not only conducive to the excellence of steel quality, but also conducive to the research and development of the steel sheet pile market; It is conducive to the optimization design of product characteristics to better meet the needs of users.

The development of special sealing and overprinting technology is a good example of this. For example, the HOESCH patent system has opened a new important field of steel sheet pile in pollution control.

Since the HOESCH steel sheet pile was used as a vertical sealed retaining wall in 1986 to protect the contaminated land, it has been found that the steel sheet pile meets all the requirements for preventing water leakage and pollution. The advantages of steel sheet piles as retaining walls are gradually widely used in other fields.

The following are some of the more effective geotechnical engineering and application environments for the application of steel sheet piles:

* Cofferdam

* River flood diversion and control

* Water treatment system fence

* Flood control

* Enclosure

* Protective dike

* Coastal revetment

* Tunnel cut and tunnel shelter

* Breakwater

* Weir wall

* Slope fixation

* Baffle wall

Advantages of using steel sheet pile fence:

* No excavation is required to minimize waste disposal

* If necessary, the steel sheet pile can be removed after use

* Not affected by topography and deep groundwater

* Irregular excavation can be used

* Construction can be carried out on the ship without arranging another site

Construction Process

Prepare

1. Construction preparation: before driving the pile, the notch at the pile tip shall be sealed to avoid soil squeezing, and the lock mouth shall be coated with butter or other grease. For steel sheet piles that have been out of repair for a long time, deformed lock mouth and seriously rusted, they should be repaired and corrected. For bent and deformed piles, they can be corrected by hydraulic jack jacking or fire drying.

2. Division of pile driving flow section.

3. During pile driving. To ensure the verticality of steel sheet piles. Use two theodolites to control in two directions.

4. The position and direction of the first and second steel sheet piles to be driven shall be accurate, so as to play the role of guiding template. Therefore, the measurement shall be made once every 1m of driving, and the reinforcement or steel plate shall be welded with the purlin support for temporary fixation immediately after driving to the predetermined depth.

Design

1. Selection of driving method

The construction process of steel sheet piles is the separate driving method, which starts from one corner of the sheet wall and is driven one by one (or two in a group) until the end of the project. Its advantages are simple and rapid construction and no need for other auxiliary supports. Its disadvantages are that it is easy to tilt the sheet pile to one side, and it is difficult to correct after error accumulation. Therefore, the separate driving method is only applicable to the case where the requirements of sheet pile wall are not high and the length of sheet pile is small (such as less than 10 m).

2. The screen driving method is to insert 10-20 steel sheet piles into the guide frame in rows, and then drive them in batches. During driving, the steel sheet piles at both ends of the screen wall shall be driven to the design elevation or a certain depth to become positioning sheet piles, and then driven in the middle in steps of 1/3 and 1/2 sheet pile height. The advantages of the screen driving method are: it can reduce the accumulation of inclination error, prevent excessive inclination, and it is easy to achieve closure and ensure the construction quality of the sheet pile wall. The disadvantage is that the self-standing height of the inserted pile is relatively high, and attention should be paid to the stability and construction safety of the inserted pile.

3. Driving of steel sheet piles.

During pile driving, the driving position and direction of the first and second steel sheet piles to be driven should ensure accuracy. It can play a role of template guidance. Generally, it should be measured once every 1m driven. The construction of corner and closed closure of steel sheet pile can adopt the special-shaped sheet pile, connector method, overlapping method and axis adjustment method. In order to ensure safe construction, it is necessary to observe and protect important pipelines and high-voltage cables within the scope of operation.

4. Removal of steel sheet piles.

When backfilling the foundation pit, the steel sheet pile shall be pulled out for reuse after finishing. Before extraction, the extraction sequence, extraction time and pile hole treatment method of steel sheet piles shall be studied. In order to overcome the resistance of sheet piles, according to the pile pulling machinery used, the pile pulling methods include static pile pulling, vibration pile pulling and impact pile pulling. During the removal operation, pay attention to observe and protect the important pipelines and high-voltage cables within the scope of operation. [1]

Equipment

1. Impact piling machinery: free fall hammer, steam hammer, air hammer, hydraulic hammer, diesel hammer, etc.

2. Vibratory pile driving machinery: This kind of machinery can be used for both driving and pulling piles, and the commonly used is the vibratory pile driving and pulling hammer.

3. Vibration and impact pile driving machine: this kind of machine is equipped with an impact mechanism between the body of the vibration pile driver and the clamp. When the vibration exciter generates up and down vibration, it produces impact force, which greatly improves the construction efficiency.

4. Static pile driving machine: press the sheet pile into the soil by static force.